8/7G R.Shukhevych str., Khmelnytskyi Ukraine 29025

Mon-Fri: 8:00-17:00

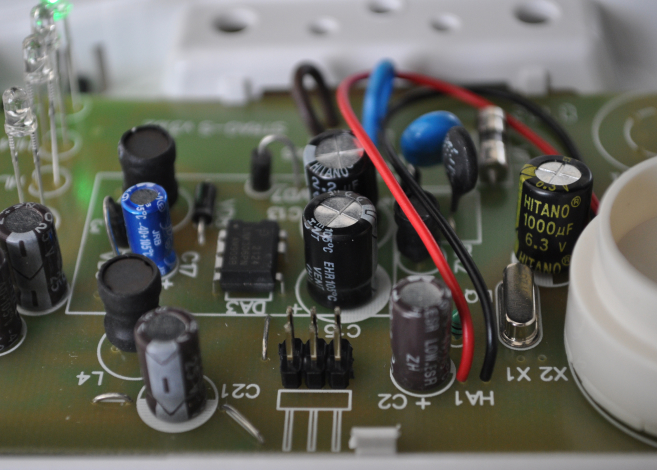

This service includes a whole range of services, including:

- Supply of printed circuit boards, electronic components, solder paste stencils;

- Automated assembly of SMT components (SMD assembly);

- Installation of THT components (automated or manual) (DIP installation);

- Two-stage inspection of mounted boards using the automatic optical inspection (AOI) system and visual evaluation;

- Attaching components to printed circuit boards using glue;

- Installation of housing elements, radiators, etc.;

- Cleaning of printed circuit boards;

- Conformal coating;

- Programming ("firmware") of microcontrollers and memory chips;

- Calibration;

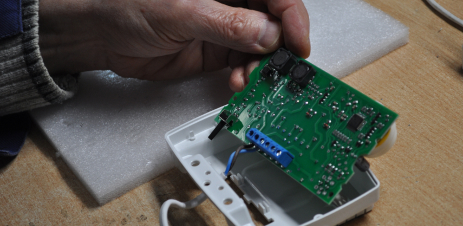

- Assembling the device into a box;

- Functional testing of the board and/or device as a whole.

The request for this service must contain the following information:

Requirements for a printed circuit board: material, board thickness, copper thickness, type of solder.

RS-274X format GERBER files.

Requirements for board surface treatment – cleaning, coating, varnishing, etc.

Assembly drawing files, and additional specific requirements for mounting components on the board.

BOM files (Bill of material), or specification. If our offer should include the purchase of components, then their description should be as detailed as possible: operating temperature range; permissible deviations from the nominal value; body type; temperature coefficients; maximum working voltage; critical dimensions.

If the component does not have additional information, we will select it ourselves. All components selected by us will be presented to the customer for acceptance.

Any other information about the project that you consider necessary to inform us.

Number of circuit boards, order size (pieces), desired term.